Wondering what the EN1822 filter standard is, and when to use it? This articles covers the scope and history of the EN1822 standard, how filters are classified to the EN1822 standard, and how they are tested.

EN1822 Filter Standard: Overview

EN1822 and its latest version, the EN1822:2019 is the European standard for filters for use in the field of ventilation and air conditioning. It classifies filters into groups based on their filtration efficiency, and provides a method to test the performance of air filters, and set out requirements for the quality and manufacture of air filters.

The EN1822 standard was first specified in 1998, and has been updated several times to the latest version in use today – the EN1822:2019 standard. The standard is split into 5 parts, with parts 2 to 5 having been replaced by the EN ISO 29463 standard – an international standard for air filters.

Part 1: Classification, performance testing, marking (EN1822-1:2019)

Part 2: Aerosol production, measuring equipment and particle-counting statistics (EN ISO 29463-2)

Part 3: Testing flat sheet filter material (EN ISO 29463-3)

Part 4: Test method for determining the leakage of filter element – Scan method (EN ISO 29463-4)

Part 5: Test method for filter elements (EN ISO 29463-5)

Filter classifications of the EN1822 Standard

Under the EN1822 standard, filters are split into three groups according to their filtration efficiency:

*Group E: EPA filters (Efficient Particulate Air filter)

*Group H: HEPA filters (High Efficiency Particulate Air filter)

*Group U: ULPA filters (Ultra Low Penetration Air filter)

Below are the 8 different classes defined under the EN1822 and their filtration efficiency. Efficiency is defined as the filtration efficiency against the most penetrating particle size (MPPS).

| Filter Class (EN 1822) | Filter Class (ISO 29463) | Overall Efficiency (%) |

|---|---|---|

| E10 | – (not covered) | ≥ 85 |

| E11 | ISO 15 E | ≥ 95 |

| E12 | ISO 25 E | ≥ 99.5 |

| H13 | ISO 35 H | ≥ 99.95 |

| H14 | ISO 45 H | ≥ 99.995 |

| U15 | ISO 55 U | ≥ 99.9995 |

| U16 | ISO 65 U | ≥ 99.99995 |

| U17 | ISO 75 U | ≥ 99.999995 |

There are other standards around the world that classify HEPA filters differently, such as the MIL-STD-282 and MERV standards in the US.

Requirements of the EN1822 Standard

In addition to assigning a rating according to a filter’s filtration efficiency, the EN1822 standard has additional requirements for air filters.

These include:

The filter should have clear marking to prevent incorrect mounting

The filter should be designed so no leakage occurs along sealing edge

The filter should be made of material that can withstand typical usage as well as the environment it is likely to encounter

Dusts or fibers released from the filter into the air should not be harmful to those exposed

When Should the EN1822 Standard be Used?

The EN1822 standard defined the scope of the standard to cover “the field of ventilation and air conditioning”, as well as for technical processes such as the pharmaceutical industry. This means the EN1822 standard was not designed to be used for air filters and HEPA filters to be used in standalone air purifiers in homes, schools, businesses.

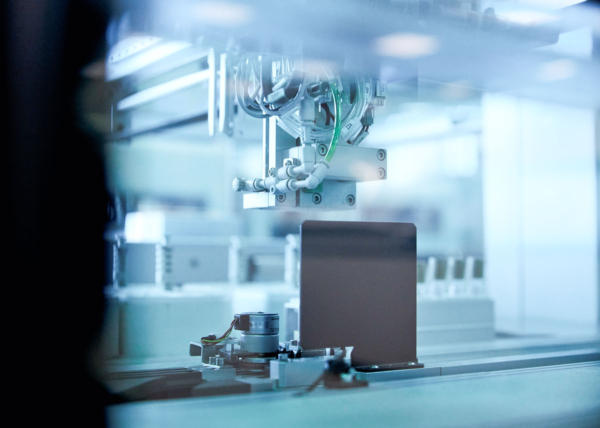

A specific use case the EN1822 standard was made for: a clean air room in the microchip industry

While the EN1822 is a good starting point for standardising HEPA filters inside air purifiers, it may not be entirely relevant. Other standards such as the GB 18801 and AHAM AC-1 standards may be better suited for portable air purifiers.

How are HEPA Filters Tested?

Liquid aerosols are typically used to test the filtration efficiency of a HEPA filter against the most penetrating particle size. There are three steps involved when testing HEPA filters under the EN1822 standard:

Step 1: Testing sheet filter medium

Step 2: Leak test of the filter element

Step 3: Efficiency test of the filter element

The testing procedure is not simple and involves serious equipment. For detailed information on the EN1822 standard test procedures, check out the EN1822 standard manual. The manual was updated in 2009, and then again most recently in 2019.

Contact: Cindy

Phone: +86-13751010017

E-mail: sales@iecgauges.com

Add: 1F Junfeng Building, Gongle, Xixiang, Baoan District, Shenzhen, Guangdong, China